Our resources

With its production tool, its premises with a workshop surface of 2700m2, a storage area of 750 m2, Hydrotec can accommodate very large cylinders.

Because of its human-sized organization, procedures and circuits are streamlined between launch, supply and production. This gives it a very high reactivity.

Discover our workshop and our high performance machines, dedicated to pneumatic and hydraulic cylinders

Workshop Repair and finishing of parts

Hydrotec is an expert and certified team that can meet all your requirements in the

in the shortest possible time.

For your custom parts, our machinist has a real unique know-how acquired through

He works on a conventional lathe and can quickly produce your part.

Our technicians have received training in Periodic General Checks (VGP) to ensure a complete service and the proper functioning of your equipment.

Stock of raw materials

Because we have a large stock of raw materials of more than 250 references, among the most used we can find S355, 42CD4, chromium-plated rectified steel, stainless steel, bronze alloy, KNO, grey cast iron… but also a complete stock of joints which allows us to repair your cylinders in the best delays.

Moreover, we have privileged partners from whom we can quickly obtain supplies for more specific materials or dimensions. This workshop includes a numerically controlled saw as well as a manually controlled saw to be able to cut the blanks and raw materials to the desired length.

Hydraulic test center

After repair we systematically test your hydraulic cylinder on our test bench which has a capacity of 700 bars maximum. At your request we can provide you with a test certificate stating the conditions and results of the hydraulic test.

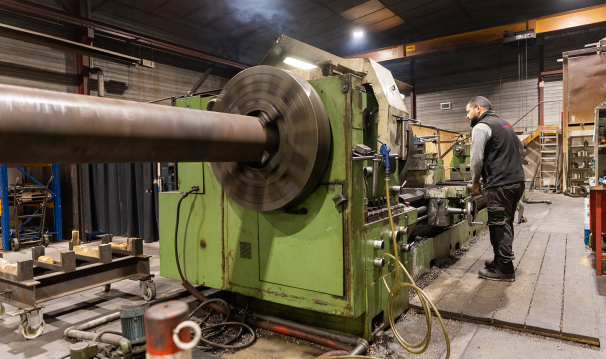

Turning workshop

We have two large-capacity conventional lathes (e.g. diameter 1000 mm, length 8000 mm) and two medium-capacity conventional lathes, as well as a numerically-controlled turning shop consisting of three medium-capacity NC lathes for more complex machining operations, and a machining center where small series of parts can be produced including turning and milling. This workshop is run by four turners.

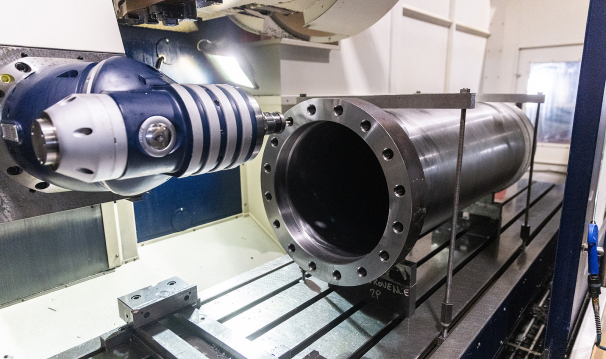

Milling workshop

This milling workshop is composed of four numerically controlled (NC) machines, including a SORALUCE TA-35-A, which is a high-capacity NC milling machine (up to 7,800 kg) that allows for large roughing passes as well as quality finishing thanks to a rigid and stable table.

In addition, two medium-capacity NC milling machines allow us to produce “more conventional” parts and an NC drilling machine used for simple drilling systems. This workshop is run by two milling machines.)

Assembly/disassembly workshop

These workshops are physically separated into two stations. They are equipped with handling equipment such as jib cranes up to 250 kg and overhead cranes up to 5 tons, as well as all the necessary tools.

These two workshops allow us to intervene on cylinders of all dimensions in perfect autonomy.)

Expertise workshop

Our expert has all the necessary measuring and control equipment to check the functional dimensions. He identifies the different components and detects the causes and material consequences of the malfunction of your cylinder.

They trust us

News

The different machining capacities

Machining by material removal is always carried out by grouping the operations by category. There are 4 important classes in traditional machining.

Modifications and improvements to your equipment

Upon receipt of your cylinders at Provence Hydraulique’s premises, an expertise will be carried out in order to identify the source of the failure or breakage.

What is a cylinder

A pneumatic cylinder is an actuator in the form of a cylindrical tube. Its mission is to create a mechanical movement.

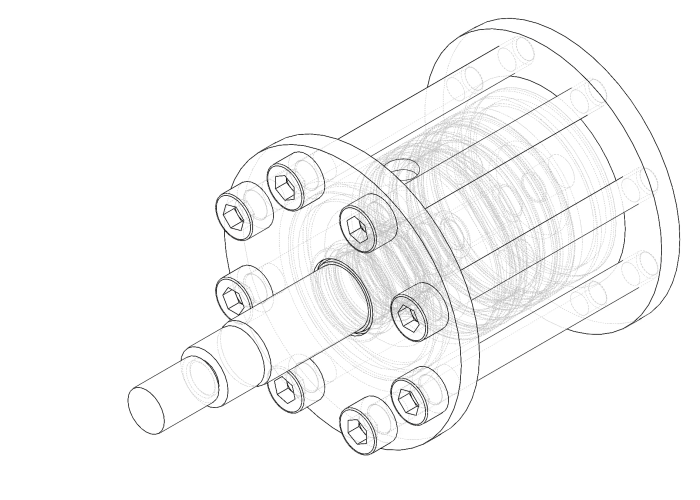

Our design office goes from 2D to 3D

Hydrotec provence hydraulique provides its customers with skills in mechanical design in order to put into shape your different ideas, prototypes and projects.

Discover Hydrotec the company

Provence Hydraulique, also known as HYDROTEC, is a French company specialized in the study, manufacture, repair and sale of hydraulic and pneumatic cylinders and their associated parts.

Cylinder path

At Hydrotec, we take it very seriously to establish a climate of trust between you and us. We have decided to present you the cylinder path in the center of our workshop.

Provence Hydraulique is ISO 9001 certified

It is a great honor and pleasure for us to announce that Hydrotec Provence Hydraulique is certified ISO 9001 since April 2022.